Agitated Ray Actuated Construction in High/No-Atmosphere Environments

A finely tuned laser beam can induce a thermal gradient in a sample, creating a through-thickness difference in thermal expansion and yield strength. This can trigger localized plastic deformation, bending the sample along the irradiated line. The effect works across a wide range of materials (even those with limited ductility), enabling a broad variety of geometries. It may also be easier to adapt for space-based manufacturing than heavy, equipment-intensive forming techniques.

This process shows great promise for use in outer space, but the state-of-the-art currently lacks a thorough understanding of the effects of environment on the laser bending process. We conduct laser bends in various environments–atmospheric pressure air, low pressure air, vacuum, and atmospheric pressure argon–and analyze the bend rate and temperature profiles developed during the bending process. We also look at the changes in surface that develop during laser bending, primarily ablation and oxidation.

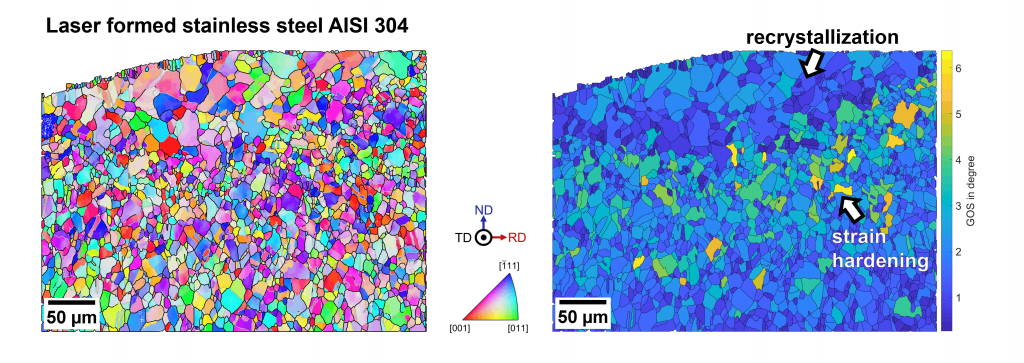

To precisely control bending, the role of microstructure is often underestimated. Published work shows that the initial microstructure strongly influences how a material responds to laser. At the same time, the microstructure can be locally altered during processing due to the imposed heat and strain, and these changes can also affect the bending behaviors—alongside other key factors.

The primary mechanism of laser forming is the thermal gradient mechanism (TGM) in which the sample bends towards the laser, but there is a second mechanism, the buckling mechanism (BM), in which the sample can bend either away from or towards the laser. The transition between the TGM and BM is a vague and poorly defined parameter space that hampers the full utilization of laser forming as a manufacturing process. We have developed a semi-analytical thermal model, that, when paired with experimental measurements, is proving an accurate method of predicting the transition between the BM and the TGM.

We not only look at the micro-scale effects of the laser forming process on the material, but also how to plan out and assemble macro-scale structures. Through careful path planning and the use of an xy-stage, we can assemble large tubes over a foot in length.

Research Activities: Bending metal samples in laser, image and video analysis through MATLAB, thermal models, Finite Element Analysis (FEA) models, Scanning Electron Microscopy (SEM)/Electron Backscatter Diffraction (EBSD), X-ray Photoelectron Spectroscopy (XPS), connecting vacuum chambers, anodizing

Current Group Members Involved: Tianchen Wei, Nathan Fripp, Partha Das, Benjamin Begley

Recent Publications:

- T. Wei, N. Fripp, B. Anthony, B.A. Begley, & V.M. Miller. Laser Bending Behavior of Austenitic Stainless Steels and Characterization of the Resultant Microstructures. Journal of Materials Engineering and Performance 34, 8941–8952 (2025). https://doi.org/10.1007/s11665-025-10708-6

- B. Anthony, N. Fripp, T. Wei, B.A. Begley, & V.M. Miller. Probing the Role of Temperature-Dependent Material Property Profiles During Laser Forming Via Finite Element Analysis. Lasers in Manufacturing and Materials Processing 11, 661–676 (2024). https://doi.org/10.1007/s40516-024-00263-8