Dr. Miller’s research interests include defect and structural evolution in crystalline material and experimental characterization via advanced electron microscopy techniques. She is particularly focused on deformation processing of metals and the associated microstructural evolution, particularly texture evolution, recovery, and recrystallization. Her group’s primary focus is on linking macroscopic processing phenomena to micro- and nanoscale mechanisms, enabling the development of predictive material models for engineering applications. Much of the group’s work has been in thermomechanical processing of low-symmetry metals including titanium alloys for aerospace and magnesium alloys for automotive and consumer electronic applications.

Current Projects

HeRX in γ/γ’ systems: Data-Driven Recyrstallization Analysis (Hγγ’DRA)

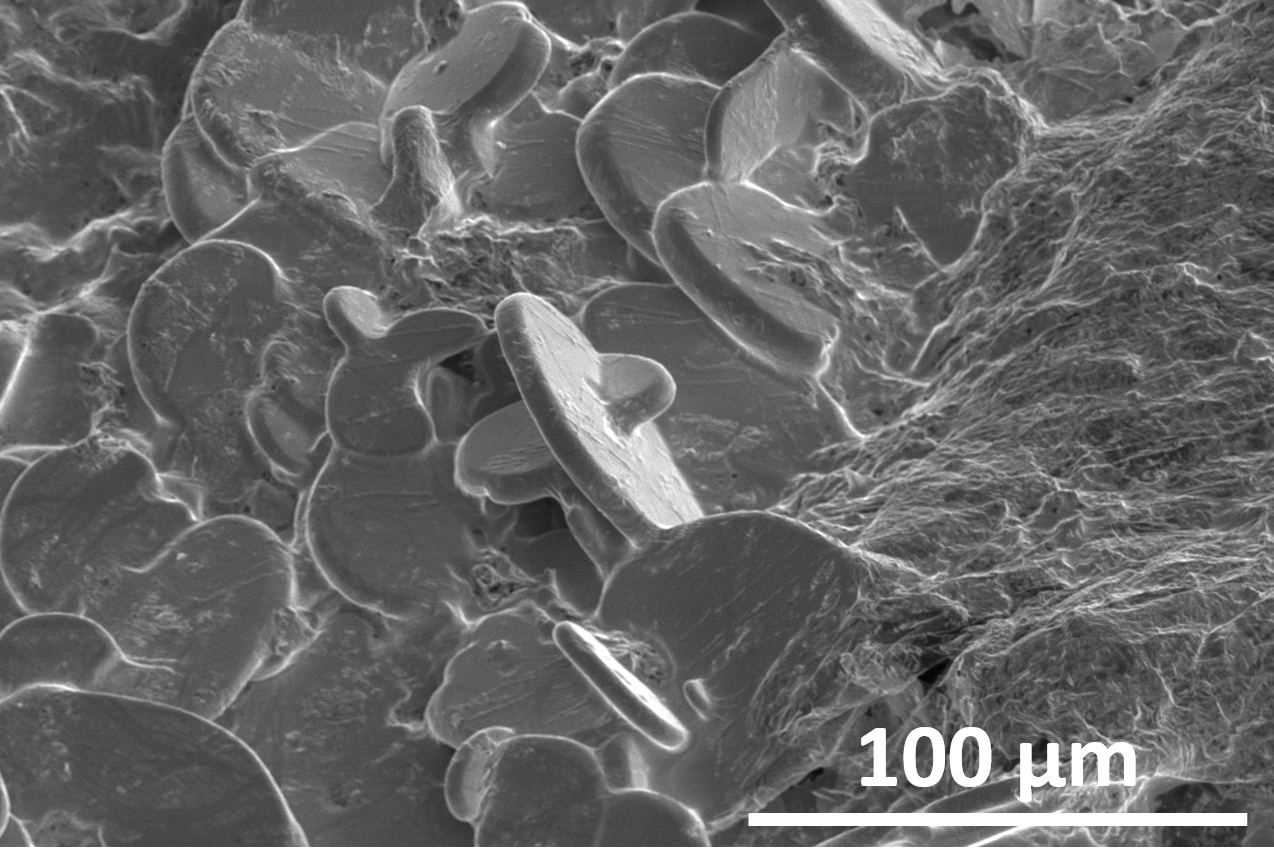

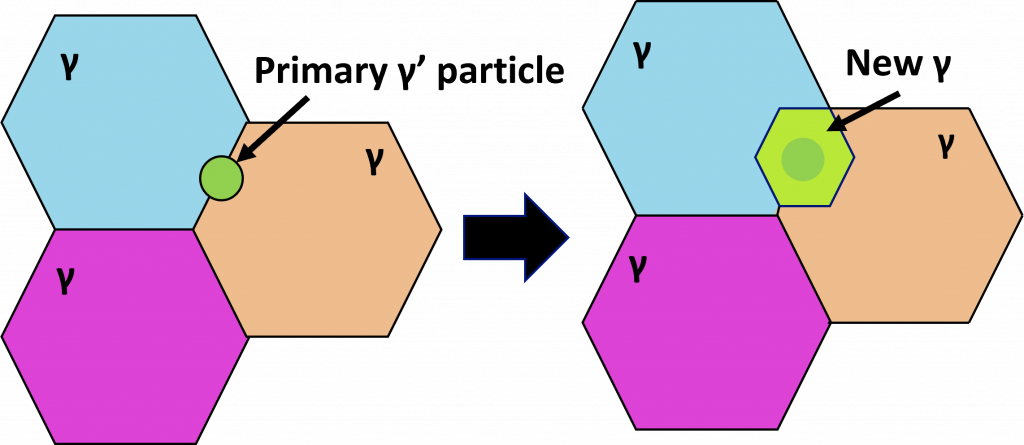

Heteroepitaxial Recrystallization is a strain driven recrystallization mechanism discovered to occur in gamma-gamma prime Ni-superalloys. HeRX is a mechanism of concern since it can lead to abnormal grain growth in superalloys, however the mechanism also hold’s promise for alternative processing methods resulting in recrystallization. The goal of this research is to determine which systems HeRX can occur in, which variables effect and activate the mechanism, and how the mechanism can be controlled.

Research Activities: Polishing of Ni and Co Base Superalloys, Scanning Electron Microscopy (SEM), Electron Backscatter Diffraction (EBSD), Energy Dispersive Spectroscopy (EDS), Image Processing using MATLAB and the MTEX toolbox.

Current Students Involved: Yonguk Lee

Recent Publications:

- Lee, Y., Hale, C., Payton, E.J., & Miller, V.M. (2024). On the Formation of Multiply Coherent γ Grains in a Powder Metallurgy Ni Base Superalloy. In: Cormier, J., et al. Superalloys 2024. ISS 2024. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-031-63937-1_73

- Lee, Y., Hershkovitz, E., Kim, H., Wertz, K.N., Payton, E.J., & Miller, V.M. Prevalence of Heteroepitaxial Recrystallization in the Low Solvus High Refractory (LSHR) γ–γ′ Superalloy. Metallogr. Microstruct. Anal. 13, 114–129 (2024). https://doi.org/10.1007/s13632-023-01036-z

Globularization In α/β and Near-α Titanium Alloys (GIαNT)

Like magnesium, titanium alloys are of critical interest to the aerospace, transportation, and defense industries, but unfavorable lamellar microstructures develop during initial processing steps. Costly and energy intensive thermomechanical processes are required to transform the microstructure to one favorable for end use. This project seeks to understand the underlying mechanisms of this microstructural evolution (called globularization) in order to promote the development of more efficient processing procedures.

Research Activities: Scanning Electron Microscopy (SEM), Electron Backscatter Diffraction (EBSD), Viscoplastic Self-Consistent (VPSC) Modeling

Current Students Involved: Benjamin Begley

Agitated Ray Actuated Construction in High/No Atmosphere Environments (ARACHNE)

A finely tuned laser beam can induce a thermal gradient in a sample, causing a through thickness differential in thermal expansion and yield strength that can induce plastic deformation. This phenomenon works on a wide variety of materials regardless of ductility to create a staggering array of geometries, but little is known about the microstructural evolution during the process. Additionally, difficulties in predictive modeling for multiple passes makes laser forming currently impractical for large scale industrial applications. This project seeks to properly predict and characterize the effects of multi-pass laser forming on various space ready materials in atmospheric and vacuum conditions for on-orbit construction.

Research Activities: Bending metal samples in laser, image and video analysis, thermal models, FEA models, SEM/EBSD

Current Students Involved: Tianchen Wei, Nathan Fripp, Benjamin Begley

Recent Publications:

- Anthony, B., Fripp, N., Wei, T., Begley, B.A., & Miller, V.M. Probing the Role of Temperature-Dependent Material Property Profiles During Laser Forming Via Finite Element Analysis. Lasers Manuf. Mater. Process. 11, 661–676 (2024). https://doi.org/10.1007/s40516-024-00263-8

Magnetic field-induced Anisotropic Tailoring of Iron-Carbon Alloys for Optimal Transformation Evolution (MANTICORE)

Motivated by concerns over the energy-intensive nature of current steel heat treatment processes in industry, Induction-Coupled Thermomagnetic Processing (ITMP) was developed as a promising, energy-efficient alternative. By combining induction heating with a high, static magnetic field, ITMP accelerates heat treatments and significantly improves in the mechanical properties of steels and other ferrous alloys. Despite its potential, fundamental knowledge gaps hinder the progression of ITMP towards industrial implementation. This project aims to address some of those gap by investigating the magnetic field-induced modifications of ITMP on the phase transformation kinetics of martensite and pearlite in iron-carbon steels.

Research Activities: Scanning Electron Microscopy (SEM), Electron Backscatter Diffraction (EBSD), Parent Austenite Grain Reconstruction, Optical Image Analysis.

Current Students Involved: Megan Hurley

Solid-Liquid Interface-driven Microstructural Evolution (SLIME)

Liquid Metal Embrittlement (LME) is a phenomenon in which a typically ductile solid metal becomes brittle or otherwise weakened in a particular liquid metal environment. Despite millennia of documented observation and over a century of active investigation, the underlying mechanisms of LME remain poorly understood. As liquid metals have found increased interest in the fields of microelectronics and nuclear fusion, it is more important than ever to be able to predict LME in critical environments. This project seeks to untangle the complex web of microstructural interactions and evolutions seen in various systems in order to predict the destructive (and sometimes beneficial) effects of liquid metals.

Research Activities: Polarized optical microscopy, scanning electron microscopy (SEM), electron backscatter diffraction (EBSD), Thermo-Calc, and a whole lot of putting liquid metals on solid metals

Current Students Involved: Mayo Mizak

Past Projects

Data Science Enabled Mechanistic Investigation of Liquid Metal Infiltration, Cracking, and Chemical Attack (DEMILICH)

Liquid Metal Embrittlement is a phenomenon in which a typically ductile solid metal becomes brittle or otherwise weakened in a particular liquid metal environment. Despite being studied for over 100 years, no proposed mechanism exists that satisfactorily describes even a majority of liquid metal embrittlement systems, and no model has been developed that can predict whether and given liquid-solid metal couple will result in embrittlement. The goal of this project is to leverage modern data science and machine learning techniques to identify previously hidden trends in historical data, and to guide experimentation to develop a model of LME to enable prediction and to reduce the hazard posed to emerging liquid metal based technologies such as flexible gallium based conductors or liquid cooled nuclear reactors.

Research Activities: Datamining, Clustering Analysis, Machine Learning, Mechanical Testing, In-Situ Scanning Electron Microscopy, Electron Backscatter Diffraction (EBSD), Thermo-Calc.

Current Students Involved: Justin Norkett

Improving Formability at Room Temperature by Inhibiting Twin Transfer (IFRIT)

Magnesium alloys are of critical interest to the aerospace, automotive, and defense industries, but are currently limited in use due to poor ductility and formability at room temperature. Magnesium’s plastic anisotropy and lack of active slip systems under ambient conditions result in excessive twinning and rapid texture formation, ultimately resulting in brittle failure. This project seeks to investigate the ways intermetallic particles modify and inhibit twinning behavior within these alloys, and to determine the role these intermetallics play in generating localized stress states that can activate additional slip systems at room temperature.

Research Activities: Mechanical Testing, Scanning Electron Microscopy, Electron Backscatter Defraction, Twinning Analyis, Full-Field Viscoplastic Fast Fourier Transform (VPFFT) modeling

Current Students Involved: Benjamin Anthony