Magnetic field-induced Anisotropic Tailoring of Iron-Carbon Alloys for Optimal Transformation Evolution

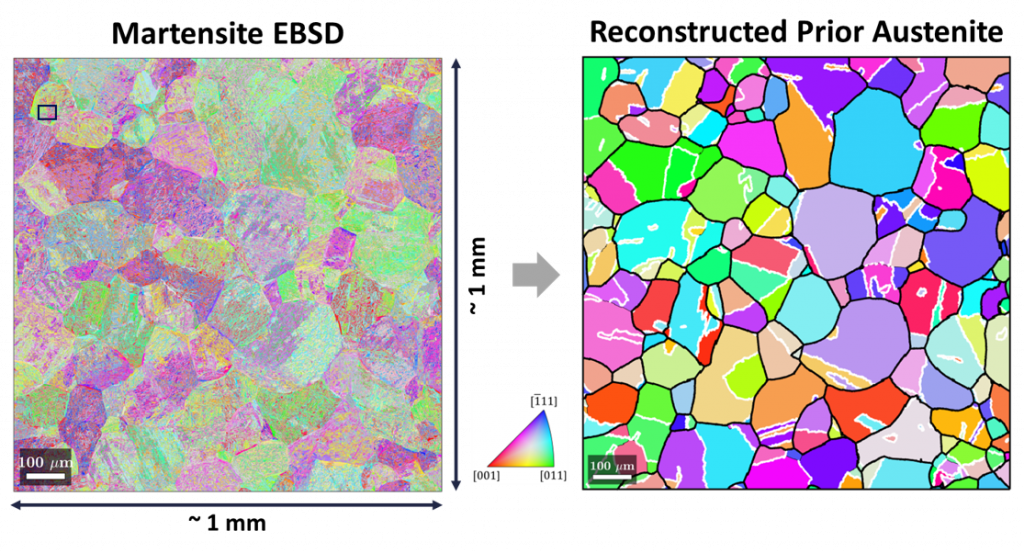

Magnetic field-assisted processing is a developing, energy-efficient alternative to current heat treatment processes in the steel industry, which leverages a high static magnetic field to improve processing outcomes. Attempts to precisely tailor steel microstructures using magnetic field-assisted processing are hindered by poor understanding of how the field alters microstructural evolution. In this project, we use electron backscatter diffraction to examine martensite morphologies and reconstruct prior austenite microstructures to reveal the effects of processing under varied magnetic field strengths, annealing times, and heating methods.

Research Activities: Performing in-field heat treatments of low-alloy carbon steels, Scanning Electron Microscopy (SEM), Electron Backscatter Diffraction (EBSD), Analyzing martensite microstructures and reconstructing parent austenite grains using MTEX toolbox and ORTools, and Dealing with BIG DATATM using HiPerGator.

Current Group Members Involved: Megan Hurley

Recent Publications:

- M.E. Hurley, R.K. Bollineni, A.M. Donald, S. Flynn, J.J. Hamlin, M.S. Kesler, M.V. Manuel, M.W. Meisel, L. Li, & V.M. Miller. Microstructural Evolution of Steel During Magnetic Field-Assisted Processing. JOM 77, 2862–2874 (2025). https://doi.org/10.1007/s11837-025-07240-2